The medical industry is an ever-growing industry, and it keeps experiencing innovations and product launches. Numerous types of medical devices are being used in different medical sectors and one of them is the orthopedic industry. The devices that are used in this medical sector are known as orthopaedic implants and instruments. In this post, we will be discussing orthopedic implants in detail and take a deep dive into what they are along with their uses.

What Are Orthopaedic Implants?

Orthopedic implants are medical devices that are made to fix broken bones surgically. Not only this but, trauma implants are also used to replace bones in cases where repair work is not possible. Sometimes, the damage to the bone is so severe that an artificial limb is applied.

Advancements and innovations in the designs of orthopedic devices have been the biggest factor in the growth of the orthopedic industry. Thousands of different types of orthopedic implants and instruments are there in the market. And the best part about that is each one has a specific use.

In the last few decades, the orthopedic industry has seen massive changes and that has made the treatment of severe orthopedic injuries possible that were considered difficult to treat earlier. Not only do the implants assist in fixing the injured bone but they can also replace the articulating surfaces of the different joints of the body.

Orthopedic devices are fixed inside the body and hence, they are made using biocompatible non-metals and metal alloys. Implants are also used to replace a damaged joint in cases where the joint cannot be repaired. In such cases, special implants that are made to be used in different joints of the body are used.

What Are the Uses of Orthopaedic Implants?

Well, some people do ask what the need for orthopedic implants is or if they can only fix traumatic orthopedic injuries. In this section, we will see the uses of orthopedic implants in detail.

The most known use of orthopedic implants is the fixation of broken bones. Now, there are multiple causes of fractures, and they may include:

- Trauma like automobile accidents, contact sports injuries and falling from a height

- Conditions like osteoporosis and others that make bones weak

- Aging as elderlies are more prone to fractures

- Sedentary lifestyle

- Poor postural techniques

Orthopedic implants provide stability to the broken bone(s) while allowing them to heal.

Besides traumatic injuries, trauma implants are also used to treat other orthopedic conditions that include limb length deformities, congenital disabilities, and degeneration of bones because of a chronic health condition.

Above all, the orthopedic surgeon may also recommend using trauma implants and instruments to provide relief from age-related or activity-related joint pain if it does not improve with conventional treatments.

So, we must say that orthopedic implants have many uses beyond treating a fracture surgically.

What Orthopaedic Implants Are Made of?

Implants can be made of various types of metals and metals where stainless steel has been the choice of metal. The raw materials used are of medical grade to ensure biocompatibility when applied into the human body. Besides steel, titanium is also a great choice to manufacture orthopedic implants considering its mechanical and biological properties, but it is expensive. Still, some implants are only available in titanium. Here are the raw materials used to manufacture trauma implants:

Stainless Steel

Stainless steel has been used to manufacture countless advanced and regular implants that are used in the field of orthopedics. Specifically, SS grade 316L is the medical grade alloy that is mostly employed to manufacture implants. This grade is a combination of iron, chromium, nickel, and molybdenum.

Different types of orthopedic devices like screws, plates, nails, rods, and rigid intramedullary nails are made of medical-grade stainless steel.

The reason why the alloy is being used the most is that it does not corrode in the oxygen-rich environment of the body. Secondly, it is also a widely available metal. Besides all this, stainless steel is also praised for its good mechanical properties. Hence, orthopedic surgeons trust the alloy to be used for fixing bone fractures.

Titanium and Titanium Alloys

Titanium and titanium alloys are commonly used in the manufacturing of most orthopedic implants. Most components of the total hip femoral stem along with intramedullary rods contain titanium alloys. Besides this, titanium is also used to make various orthopedic screws and plates. Above all, titanium alloy is the choice for many spinal implants that include pedicle screws, rods, and interbody devices.

The modulus of elasticity of titanium is close to that of cortical bone and this makes it one of the best choices for manufacturing orthopedic implants. Along with this, titanium is also highly durable and light in weight. Another advantage of titanium is that it is readily workable and can be both hot and cold worked into various shapes.

Cobalt-Chrome

For bearing surfaces in orthopedics, cobalt-chrome is the most widely used metal alloy. Hence, this reason makes it the choice of alloy in arthroplasty. However, cobalt-chrome contains nickel, and surgeons avoid using arthroplasty implants made from cobalt-chrome in people with severe nickel allergies.

Cobalt-chrome has a very high modulus of elasticity and shows excellent impact resistance. This alloy can bear extreme forces before fracturing. On the other hand, despite having the ability to obtain a very smooth surface finish, Cobalt-chrome is very difficult to cut or shape.

Tantalum

Tantalum is one of the less-used metals in orthopedic surgery. Currently, it is employed for making augments. They are used for filling bone defects in the case of arthroplasty, tumors, and fractures. Augments made of tantalum can be drilled in vivo and cut & drilled in the operative theatre, and hence, this makes it a choice of metal for such applications.

Polyethylene

Different forms of polyethylene are used to make various orthopedic implants. In several implants like total hip arthroplasty, bearing surfaces are made of polyethylene. Well, the properties of polyethylene are being improved to make it better.

Ceramics

Ceramics are mostly employed in making bearing surfaces of hip replacements. The wear-resistant properties of ceramics are considered to be the best when compared to other bearing surfaces in orthopedic surgery.

What Should be the Properties of Materials used to Manufacture Orthopaedic Implants?

Now, you are well aware of the materials that are used to manufacture orthopedic devices. Certain properties make these materials suitable for making trauma implants and instruments. Let us have a look.

Biocompatibility

The first and foremost thing that needs to be considered is the biocompatibility of the raw materials. It is important because if the metal or non-metal used to make implants is not suitable to be placed inside the body, the chances of infections and other complications will become high. The body will reject the implant and serious issues may occur.

If a metal/non-metal is biocompatible, this means it is compatible with the living tissue. Hence, medical devices made can be safely implanted.

Strength

Another important property of these materials is their strength. This is because orthopaedic implants have to bear daily stress as our bones do. So, if the material is not strong, the implant will break, and repeat surgery will be on the cards to remove it. Thus, the strength of implants to bear stress makes them suitable for use.

Workability

The metals or non-metals used for making orthopedic devices must be easily workable. This means they should be easily shaped into different designs and sizes as required. It is important to make different types of orthopaedic implants and instruments with ease and precision.

Corrosion Resistance

All the metals that are used to make orthopedic implants show excellent corrosion resistance. This is why they last for years in the oxygen-rich environment inside the body.

What Are the Different Types of Orthopaedic Implants?

Thousands of different types of orthopedic devices are there in the market. Orthopedic surgeons choose implants depending on the location and severity of the fracture or other orthopedic conditions. Here, we will have a look at some of the common types of orthopedic devices available in the market.

Orthopedic Screws

Orthopedic screws are similar to the ones that we use for other purposes. Their primary function is to produce compression. This helps the injured bone to heal properly in its true anatomical position. Screws are available in different sizes, head styles (star and hexagonal), and other structural configurations.

Screws have a head, shaft(body), and tip. They are available in locking and non-locking structural configurations. Screws can be used with other orthopedic implants like metal plates or rods and alone for bone-to-bone or bone-to-tissue fixation.

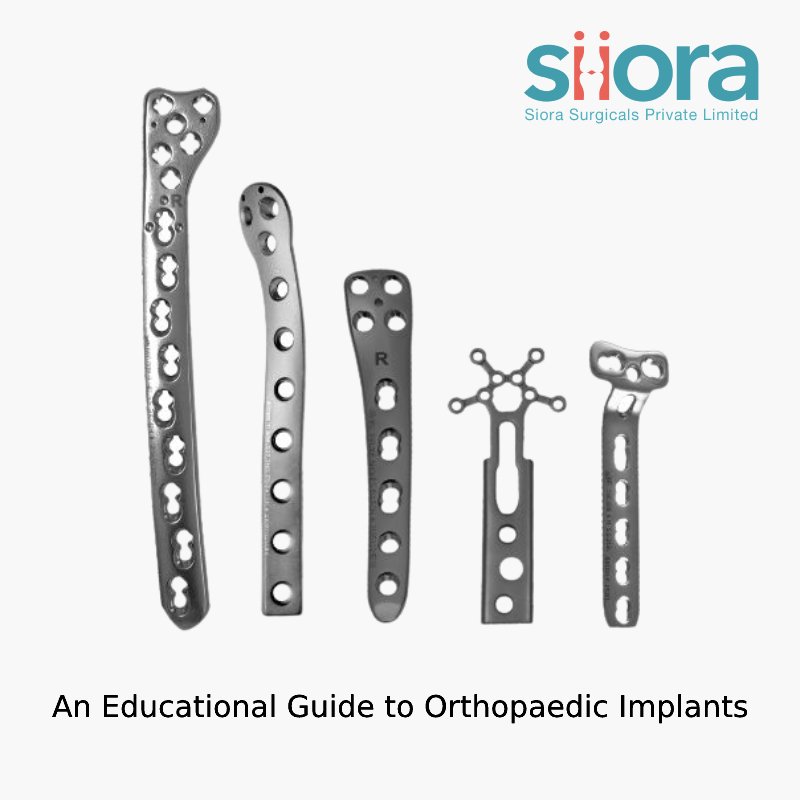

Orthopedic Plates

Orthopedic plates hold the fractured bone fragments in their correct anatomy and provide support while they heal. Numerous types of implant plates are there and the orthopedic specialist selects them based on the type, location, and severity of the fracture. Plates are the most commonly used orthopedic implants that were first used in 1886. They are available in locking and non-locking structural configurations and are paired accordingly with corresponding screws.

Siora Surgicals Pvt. Ltd. manufactures different types of orthopedic plates in pre-contoured shapes to ensure good placement according to the patient’s bone.

Different types of orthopedic plates available in the market include:

- Buttress plates

- Compression plates

- Bridging plates

- Tension plates

- Neutralization plates

Orthopedic Nails/Rods

Also known as intramedullary nails, orthopedic rods are used to fix fractures by applying them into the intramedullary cavity of the bone. They are commonly used to treat fractures of long bones and are often placed along with orthopedic screws. They are also available in titanium elastic nail forms.

Orthopedic Wires

Wires are commonly used to fix fractures in children. K-wires are among the commonest and are often suggested to treat sub-trochanteric fractures of the Humerus in kids. They are flexible and can easily be bent as required.

Another type of wire available is suture wire. Internal fixation and tendon repair are few of the common uses these wires.

Wires are also suitable for small bone fractures like phalanges, metacarpals, and metatarsals.

Orthopedic Pins

Orthopedic pins correct minimal bone fractures and soft-tissue damage. They are also helpful in providing temporary internal fixation before the application of other hardware. This minimizes the risk of incorrect permanent fixation of fractures. They are available in different lengths and diameter sizes. Some of the common types of orthopedic pins include:

- Austin Moore Pin

- Knowles Pin

- Steinmann Pin

Orthopedic Staples

Orthopedic staples are of use when there is a multi-fragmented fracture. In such cases, staples provide internal fixation and allow for bone reconstruction. They are also helpful in repairing soft tissue damage. A few of the common applications of orthopedic staples include joint surgeries, especially ankle and foot. Two common types of orthopedic staples include:

- U-Type staples

- Coventry staples

Prosthesis

In simpler terms, we can define prostheses as artificial body parts. They replace injured body parts and even joints. Hip and knee joint prostheses are a few of the common ones. Besides these two, radial head prostheses are also there. They bring back the range of motion of the injured joint and improve the quality of life.

These are the common types of orthopedic implants; some of them are placed permanently inside the patient’s body whereas some are temporary. Let us have a brief look at both.

What Are Permanent Orthopaedic Implants?

As the name suggests, permanent orthopaedic implants are those that remain forever inside the patient’s body. Once implanted, there is no need for them to be removed as the patient can lead a normal life after complete healing of the operated area. Knees, hips, ankles, elbows, wrists, and shoulders are the locations where implants are permanently placed in most cases.

In rare cases, permanent implants may be removed, especially when they are wrongly placed or start irritating the location where they are applied. In such cases, it becomes necessary to remove them and place another one with repeat surgery.

What Are Temporary Orthopaedic Implants?

Temporary orthopedic implants are often removed when the fracture has healed. Repeat surgery is performed for removing the implants. Orthopedic surgical implants that are temporarily applied include wires, pins, intramedullary nails, plates, and screws. Temporary implants are commonly used for fractures.

Screws and plates also come under permanent trauma implants.

The Bottom Line

Orthopaedic implants are among the most commonly used medical devices across the globe. It won’t be wrong to say that they are still improving in terms of size, shape, and structural configurations. They are available in thousands of different types and the orthopedic specialist choose them specifically based on the patient’s age and type of fracture.

Precision while manufacturing implants is important, as even a slight manufacturing defect, can cause severe complications. Siora Surgicals Pvt. Ltd. is a leading and one of the most trustworthy orthopedic device manufacturers operating from India. The company manufactures hundreds of different types of CE-certified orthopedic implants. It has a strong global presence and is serving around 130 national and international distributors and orthopedic surgeons. Siora has an advanced manufacturing facility in the RAI District, Sonepat Haryana, and is also an experienced OEM/contract manufacturing service provider.

Surgicals is also proud to be a regular exhibitor at the FIME Show Miami.